A Designer. A Problem Solver. An Engineer.

Building off the concepts learned from my Ground Communication for Satellite Operation course, I took it upon myself to take it a step further and not only capture and record a signal, but also demodulate it and recreate it through use of GNU Radio Companion. Due to its simplicity and easy access, I chose to use a 10 dip switch garage door opener.

Jetting water vapor, ice, and methane from its “tiger stripes” - four sub-parallel, linear depressions in the south pole region - Enceladus offers something undiscovered outside of planet Earth: potential signs of life. The goal is to launch an orbital sample retrieval mission to the Saturnian moon. The sample will be studied using the more robust instruments that cannot be put on a spacecraft, which may lead to an answer on whether life exists on Enceladus.

The marine chronometer was a significant mechanical engineering advancement in the mid 18th century. Without an accurate chronometer, mariners had no reliable and accurate way to determine longitude while sailing. In this project, my group members and I designed, built, and test a mechanical clock using 3D Experience's xDesign to model and the Ender-3 to 3D print our parts.

Within teams of three to five, our goal was to design and fabricate a joystick-controlled machine that is able to navigate a lunar landscape playing field, retrieve objects, and then deposit said objects into receptacles. Utilizing SolidWorks and Thayer’s machine shop, we designed a robot that is able to lift objects above 15 inches, a driving mechanism that allowed tight turns, and a lightweight chassis to minimize weight.

With simply an IR sensor and motor, the “Duck Car” is a black box system that is intended to stay a specified distance away from the lead vehicle both when stationary and moving. I accomplished this by first modeling the system and then designing and implementing a PD compensator to achieve a fast and well damped system.

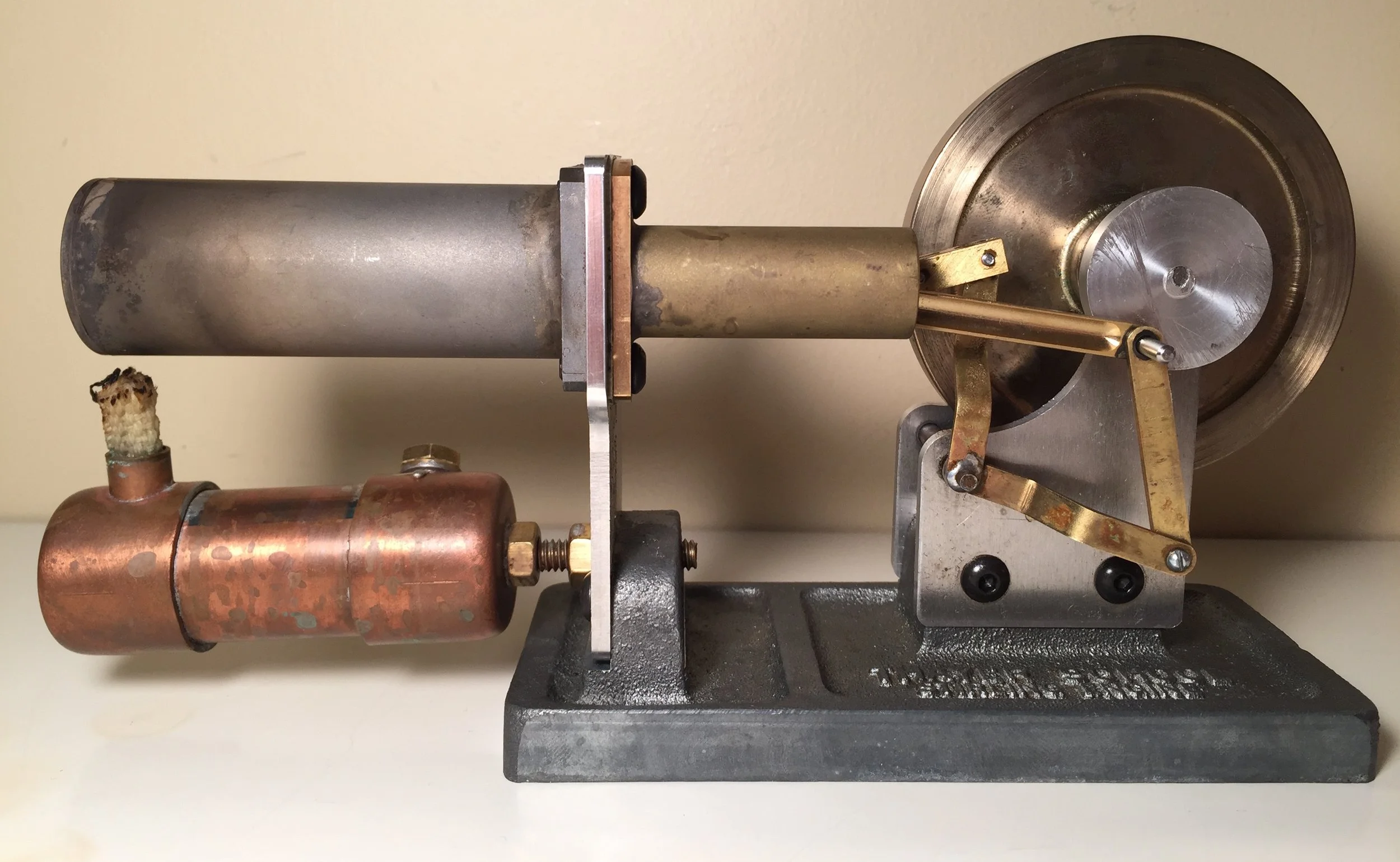

To be a true Mechanical Engineer, one must build an engine at least once. Through the use of a 2D Lathe and 3D Mill, I machined numerous components, assembled, and brazed them together to create a working Stirling Engine.