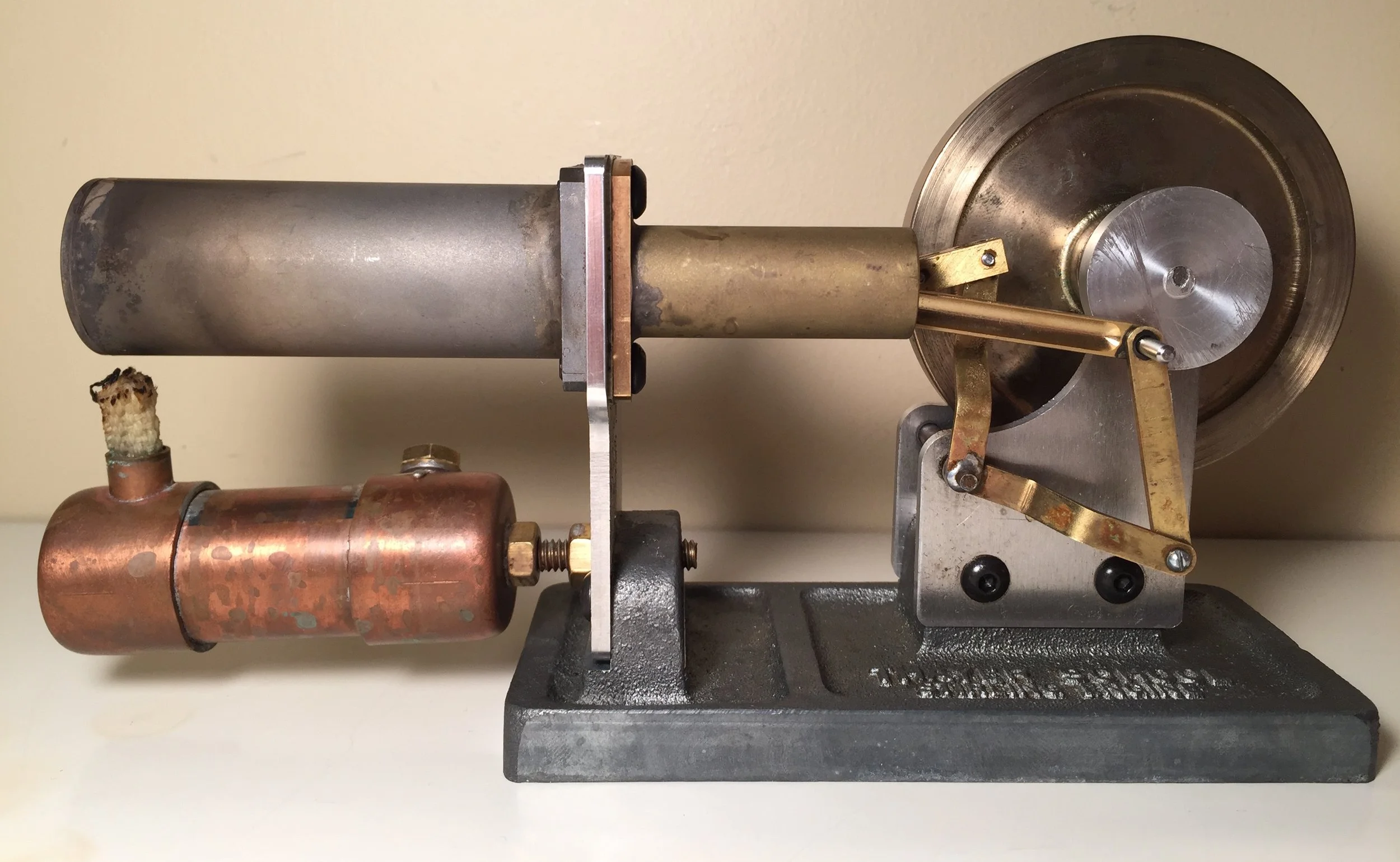

Stirling Engine

To be a true Mechanical Engineer, one must build an engine at least once. Through the use of a 2D Lathe and 3D Mill, I machined numerous components, assembled, and brazed them together to create a working Stirling Engine.

-

Over the course of 8 weeks, I reported to Thayer’s machine shop weekly where I constructed over 50 parts from scratch through the use of 2D Lathe and 3D Mill.

-

As the semester project for ENGS 25: Introduction to Thermodynamics, I was able to bring abstract classroom concepts, such as the Stirling Cycle and heat transfer, to life and develop an applied understanding of them.

-

At the end of the 8 weeks, I had a finished engine that was able to generate 698 rpm, which placed me in the top 5 in my class in terms of rpms.